So after a carefully walk around the outside of the aircraft where the Static and Pitot ports are checked un-obstructed; no indications from your EICAS that there are any problems with the Air Data System during taxi; you barrel down the runway, cross check the airspeed when you hear the call “Eighty Knots!” and see – yes, it’s 80 knots all right. We’re cool, Rock On.

Seconds later it’s laconic Auto-American calling “Vee Wun“, followed by “Rotate!” from your PM … and you’re safely airborne. You pitch up to contain your airspeed, the PM calls “Positive Climb …” and you hit back with “Gear Up“. Through the flight controls you regain that wonderful feeling of mastery and control as you guide 350 tons into the air towards your target pitch attitude of about 12 degrees …

As you pass 15 degrees with the airspeed increasing, the rate of climb exceeding all your expectations, you sense something is wrong. Further speed increase is completely unaffected by a now excessive Pitch Attitude. Suddenly you look around you and Remember. You’re in the Lurching Cave (the simulator), and this … is AIRSPEED UNRELIABLE.

Towards the bottom of this post (“The Simulated Experience“) is the continued story. But first, the section of the Procedures and Techniques document that pertains to this event.

Procedures and Techniques : AIRSPEED UNRELIABLE on Takeoff – a Sim Scenario

First – go look at Airspeed Unreliable (in Procedures and Techniques or here) … now read on. Note that all through the following you are Raw Data, Manual Thrust which for a long haul 777 pilot is high workload, high stress (at least initially). As such while the PF’s flying skills are crucial in this exercise – the PM role becomes (even more) incredibly important. Captains, once the situation is stable – time to Manage the situation from the PM role (if you aren’t already). Personally my hand flying skills improve immeasurably when I’m watching someone else do it …

The following is a suggested technique for dealing with this Simulator chestnut. It involves being ready for the failure before you go, knowing that it’s coming and having a plan ready in place – which as an Instructor/Examiner I both applaud and discourage …

Transition After Takeoff

With the onset of this problem on takeoff – you (and the AFDS) are liable to either pitch up or down away from the desired takeoff pitch until the NNM is recognised (and confirmed). Having identified things are going pear shaped – you have a choice between returning to the known, familiar pitch setting of Takeoff (about 13 degrees?) or transitioning straight to the QRH Airspeed Unreliable memory item values. If you’re well above 1000 ft AGL (which you will be if it was a pitch up failure) and clear of terrain – the QRH should be ok. If you have terrain concerns, the I would apply full thrust and hold 15 degrees until clear and ready to transition to the QRH (or 5,000 ft figures, see below). [Thanks Pete].

Level Off at 5000 Feet

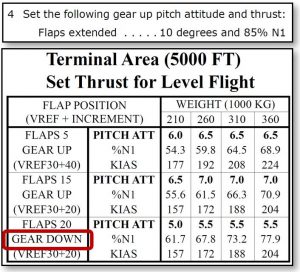

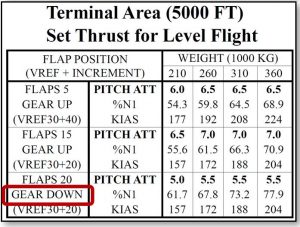

Basically, know your Terminal (target) Pitch, Power and Speed for the Weight/Flap you are taking off with. Simple enough?

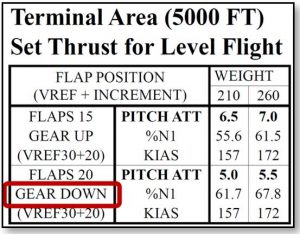

You’ll note here in the QRH PI table that for most of the weights you’re going to see (260 to 360 tons), the pitch attitude is the consistent for Flap (6.5°/7.0°/5.5°). Unfortunately, since you’ll almost certainly be selecting whatever pitch attitude gives you level flight, this won’t help as much as you’d think.

It’s all about Thrust; and for a Flap 5 Takeoff, ballpark N1’s for Takeoff Weight are:

260T – 60% (192 kts); 310T – 65% (208 kts); 360T – 70% (224 kts)

So, after the initial recognition and adoption of the Flaps Extended … Pitch 10°/N1 85% memory items – level off at 5000 feet on your altimeter, setting the power required from the QRH (by memory) and check your pitch attitude for level flight is in the ballpark of what you’d expect. If you’ve also lost altitude indication bonus points if you remembered the pitch attitude as well, because you’ll need it. Note that Boeing only provide Flap 20, Gear Down in the Terminal. If you’re taking off with Flap 20 when you level the gear will be up, so you’ll have to fudge a bit. The Gear UP / Flap 15 figures will be close … or you could select Flap 15 once you are confident you at at least the minimum power/speed. I don’t recommend lowering the gear to match the Book figures at this point …

Now wait until you get to the point in the checklist where you are required to verify the QRH Figures against the available air speeds (PFD L / PFD R / ISFD) – and do so.

Assuming you’ve actually lost all airspeed indications – having stabilised at 5000 ft at basically something just above the minimum speed for your takeoff flap setting (Vref30 +20/40/60), note your ground speed. In the sim, for as long as your headed in a constant direction, this ground speed equates to your required IAS. Gotta love the stability of the sim environment …

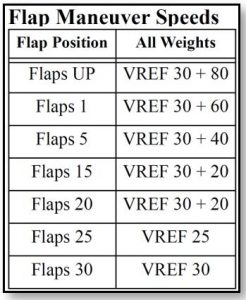

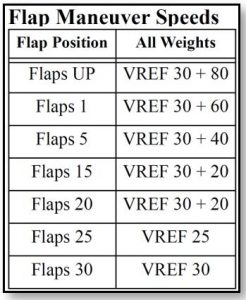

By adding 20 knots at a time you can work your way from the takeoff Flap 20 through to Flap 5, Flap 1 and then UP, 20 knots at a time, +60 knots over all. While the checklist calls for Alternate Flaps as part of the Approach Checklist – I don’t see any reason why you can’t raise the flap using the normal system, that is if you really feel the need to raise the flap at all – are you thinking of going somewhere?

Configuring for Approach

Having stabilised at clean speed, level flight – by subtracting 60 knots (20 at a time) you can work your way from Up to Flap 1, then Flap 5, and Gear Down Flap 20 for Landing. Do this manoeuvre on a constant heading, constant altitude – which should mean your reference ground speed will hold a pretty consistent relationship to your IAS for the Flap extension and deceleration sequence.

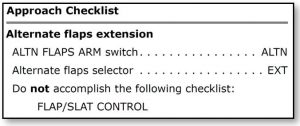

The Airspeed Unreliable checklist calls for the use of Alternate Flaps (electrical extension) which brings with it the following requirements.

The Airspeed Unreliable checklist calls for the use of Alternate Flaps (electrical extension) which brings with it the following requirements.

- Extension will be much slower (see Flaps/Slat Problems & Slower Deployment in the P&T)

- You should not reduce speed below the current Flap Minimum speed until the next Flap setting is established (see Flaps/Slat Problems & Speed Reduction in the P&T)

- Landing Flaps will be Flap 20 – and for Go-Around, stay at Flap 20.

Remember that if you change direction (and therefore the relationship between IAS/TAS/Wind Vector/Ground Speed) you need to stabilise again with a power setting that you are confident gives you the right speed for your configuration – check your ground speed, and start again. Twenty Knots at a time.

Final Approach

Final Approach

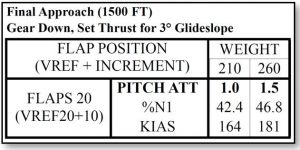

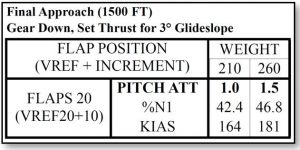

The above procedure should get you safely to Gear Down, Flap 20. Complete this well before seeking to establish your final approach path. You should be at or below Max Landing Weight – if not, you’re on your own! As you approach the glide path and establish the descent, you transition from the N1 you were using to maintain your Gear Down / Flap 20 Speed to the QRH Approach (Gear Down Flap 20) N1 setting.

Continue to monitor with ground speed. Your friend the constant ground speed/IAS relationship now varies with descent as TAS reduces to IAS; and wind backs towards the value report on the ground. The closer you get to the ground, the closer you get to a known headwind component – know in advance what kind of headwind you’re expecting late on approach, and therefore the ground speed you expect to see for your chosen Attitude/Power/IAS.

Go-Around

Go-Around

So, the first thing is – don’t Go-Around. Tell ATC you require priority. Establish final fully configured. Tell your Sim Instructor, “No Thanks.”

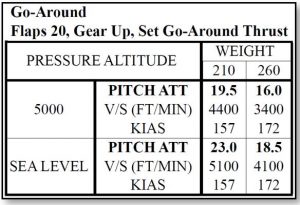

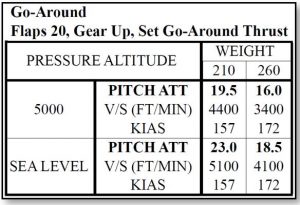

The QRH PI includes Pitch Attitudes for go-around that can take you as high as 23°. Even at 250 tons – the recommended pitch attitude is 18°. If this sounds high to you, you’re not alone. The figures are of course not wrong, and targeting them is “normal”.

If you were to encounter Airspeed Unreliable on approach and conduct a go-around without reference to the QRH – the FCTM recommends 15°. In all likelihood this will mean some measure of acceleration during your climb out, which I guess we can live with. After 20 years on the 777 I get a nose bleed above 15° of pitch anyway … unless there’s a hill in the way. As such I figure I can survive a go-around without going all the way to 23° of pitch up. And of course – don’t use the TO/GA switches.

Once again – after a go-around, climbing to a (QRH PI) known altitude such as 5000 ft and setting a power from the book makes your life just that much easier. Raising the gear in the go-around is standard – but leave the Flap at 20. As before, the QRH doesn’t have a Pitch/Power and Flap 20 speed at 5000 ft with the Gear Up. But it does have Flap 15 – so either tweak and use that; raise the Flaps to 15 – or I supposed you could lower the gear!

Once again – after a go-around, climbing to a (QRH PI) known altitude such as 5000 ft and setting a power from the book makes your life just that much easier. Raising the gear in the go-around is standard – but leave the Flap at 20. As before, the QRH doesn’t have a Pitch/Power and Flap 20 speed at 5000 ft with the Gear Up. But it does have Flap 15 – so either tweak and use that; raise the Flaps to 15 – or I supposed you could lower the gear!

Summary

The above is a suggested technique for dealing with a very much canned scenario in the sim that quite often goes badly. It assumes you know the event is going to happen, or at least things that it’s likely enough that you’re willing to expend the time and effort preparing specific mitigation against it. We do that for a lot of other events, why not this one …

The Simulated Experience

Over the past couple of decades, there have been infamous accidents of unreliable airspeed indications on the flight deck resulting in uncontrolled flight into terrain, and death. As a professional pilot, as an Instructor and Examiner, I’ve looked at some of them in detail, simultaneously wondering how those pilots got caught out and would I or my students have done better. From AF447 to JT610 (and QZ8501 in between) – it’s clears that a lack of accurate airspeed indication has the potential to kill.

I’ve just completed an Airspeed Unreliable failure on takeoff in the simulator and wanted to share the benefits of that training. In this scenario, I was the Guinea Pig in the left (rather than the Puppet Master in the Instructors seat) and the exercise was the total blockage of all three Airspeed sensing Pitot Tubes just after rotate.

I’ve recently been listening to the Flight Safety Detectives podcast. Between these two gentlemen is something like 80 years of NTSB flight safety investigation experience (apologies if I have understated that). They’ve spent nearly 7 audio-hours (not kidding!) going over the Lion Air 610 Boeing 737 Max accident. Their shocking conclusion – and I have to agree – is that this aircraft crashed and these passengers killed as a result of poor airline behaviour and poor piloting response to the Non Normal Airspeed Unreliable. Yes, the infamous MCAS was a factor in this accident – but despite the hype, not a determinative one. Go listen for yourself.

So based on that, and the knowledge that Airspeed Unreliable was coming up in my next Sim recurrent, I decided to set about completing this challenging NNM to the best of my ability. Coming as a known, planned event as it was this was my best chance to get it right. Trust me, I’ve screwed it up in the past.

In no way can this be considered a realistic exercise. First of all it was scripted as some of our training is – I knew exactly where and when it was coming. There’s value in this – when you can spend a great deal of time preparing and mentally rehearsing an exercise – and it goes well – you can take much of the learning from that into any subsequent, similar, unplanned version of that event. So I knew what was going to happen. Since one of the most important hurdles of this event is initial recognition and maintaining aircraft flight path control, that hurdle was all but jumped before we began.

I’m also Checker on the aircraft simulator – I’ve put many crew through this exercise, both planned and not planned. I’ve seen it – and written about it – before. If anyone was going to cope well with this exercise – it should be me.

Next, sitting beside me was a highly experience First Officer. Over and above that – a highly capable one (such as was not present in JT610). This is not an uncommon experience on our fleet. Being the small, wide body, internationally flying fleet in my airline – First Officer positions on this aircraft are sought after and often filled by highly experienced Captains (or First Officers with command experience) to the benefit of the entire operation. This pilot provided excellent support to me while I was tasked with controlling the beast; and when I handed it over – flew at least as well as I did. Less than 2 minutes after the Captain of JT610 handed over an aircraft that was fully capable of being flown, everyone was dead. None of that today. Nice one Brett.

Finally, our instructor today gave us a good briefing and the opportunity to discuss how we were going to handle it. It was an excellent Training Environment. Quite apart from ensuring in us a solid knowledge base – it gave the First Officer and myself the opportunity to create a shared model of what we were going to do to handle this thing. Thanks Anthony.

So … How did we do?

AIRSPEED UNRELIABLE on Takeoff

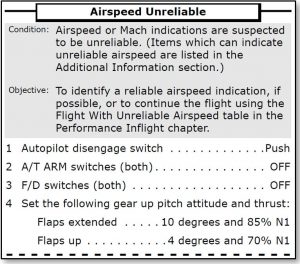

As mentioned – Recognition is absolutely crucial to this NNM. As a result – there is two pages of information as to what to look for, hidden at the back of the checklist. The Airspeed Unreliable checklist is UN-annunciated, which means the Checklist Title and Condition Statement can be considered Memory Items on top of the first few action items.

Recognition

So in this scripted scenario, the dynamic pressure Pitot tubes are blocked; and blocked good (not leaking). This means that the pressure trapped in the tubes is matched up against a progressively decreasing Static Pressure. So … your airspeed increases with Altitude (and conversely later on – decreases with Altitude until all your problems are over at the Altitude at which the blockage occurs. Well, not really).

I pitched to 12 degrees, checked the airspeed and it was still increasing. As I pitched through 15 degrees, I was waiting for that point where it was obvious that we were in a Unreliable Airspeed situation. I then called the indications to the First Officer; who agreed; and called for “Airspeed Unreliable Memory Items“. These are pretty simple.

I pitched to 12 degrees, checked the airspeed and it was still increasing. As I pitched through 15 degrees, I was waiting for that point where it was obvious that we were in a Unreliable Airspeed situation. I then called the indications to the First Officer; who agreed; and called for “Airspeed Unreliable Memory Items“. These are pretty simple.

- The Autopilot is disconnected

- The Autothrottle is disabled (not just disconnected – you don’t want it waking up)

- The Flight Directors are turned off.

Now we’re at the last stage of the memory items – the keep-you-safe-while-you-think pitch and power settings. For a Flap 5 takeoff (or any takeoff actually) this means Pitch 10 degrees and Power 85% N1. I assumed that we were probably slower than I’d like since I had raised the nose to counter the initial (falsely) increasing airspeed; so I lowered the nose to 10 degrees, then eventually reduced the thrust to 85%.

Memory Items Complete.

Transition to Book Figures

Sooner or later, you’re going to have to transition to QRH figures for Pitch and Power. When you’ve done that – you can try and work out if any of your three speed indications (Left PFD/ISFN/Right PFD) are accurate. If just one of your indicated speeds is ok (within 20 knots) – your life is just that much easier. Also today – when we checked the three speeds (at about 5000 ft) – they indicated 365 knots. Since by that time we had the power set for 190, it was clear all three were bad.

Speaking of 5000 ft – for this exercise I kept in my head the power I would need for the takeoff flap setting I had at 5000 ft after takeoff. Normally one of the first things you do after takeoff when you’ve got it airborne, the gear up and you feel like you’ve got a handle on things is to accelerate, raise Flap and initiate a high speed climb. Not today – in this case you have no airspeed with which to gauge safe acceleration to a speed at which you can raise flaps. So in this instance,

Speaking of 5000 ft – for this exercise I kept in my head the power I would need for the takeoff flap setting I had at 5000 ft after takeoff. Normally one of the first things you do after takeoff when you’ve got it airborne, the gear up and you feel like you’ve got a handle on things is to accelerate, raise Flap and initiate a high speed climb. Not today – in this case you have no airspeed with which to gauge safe acceleration to a speed at which you can raise flaps. So in this instance,

- I maintained 10 degrees / 85% N1 until we reached 5000.

- Using indicated Altitude (which was close enough to the Radio Altimeter on initial climb, and in agreement on all three instruments across the flight deck) I levelled off at 5000 ft.

- As lowered the nose at 5K, I set the power required for our weight (250T) and Flap Setting (Flap 5) which was 60% N1.

- Then I checked the Ground Speed on the ND.

Ground speed is taken from the ADIRU or GPS and is therefore unaffected by the pitot blockage. The Wind Indication however (which requires airspeed to produce the calculated result) was wildly inaccurate.

- We were 250 tons, so Flap 30 speed was 149.

- Flap 5 min speed was therefore +40 – 190 knots (near enough).

- What was our ground speed? – 205 knots.

The wind on the ground on takeoff was 10 knots, which would have increased in speed and veered in direction with ascent. At 5000 ft, indicated airspeed would be supplanted by pressure error into a higher TAS. So the indicated 205 knots was looking pretty good. In addition, the stable thrust setting of 60% N1 was holding the ground speed (bless the constant condition nature of the Sim!) so as the FO and I discussed and cross checked – we became confident in our safe control of the aircraft and it current state. This got us to the place in the checklist where we had verified that there was no accurate airspeed information available to us.

This all worked really well. In the past I have kept the QRH default 10 degrees/85% N1 values until the FO had worked his/her way through the checklist to finally drag out the QRH. This often means (at lighter weights) that you’re up above 10,000 feet before you level off. Levelling at 5000 ft using an N1 you are confident in was a great technique.

Raising the Flaps

It was now time to clean up the aircraft. Why would we do this? I’m not sure really. Since I had every intention of returning to Sydney – the safe course of action would be to leave the aircraft exactly as it was and fly around with Flap 5 out until we were ready to complicate out life and hang more Flap and Gear for landing.

However the training exercise called for us to clean the aircraft up. There may well come a time when something like this happens to you departing an airport where you really don’t want to go back – short runways lousy weather, crappy hotel. So practicing a cleanup without airspeed is a useful exercise.

Having stabilised at a supposed 190 knots (210 or so on the ground speed) – I discussed the following with my First Officer.

Having stabilised at a supposed 190 knots (210 or so on the ground speed) – I discussed the following with my First Officer.

- He obtained for me the power setting we would need to be clean at 5000 (slightly less than the 60% I already had)

- I would increase thrust, maintaining level flight at 5000, and as the ground speed increased, at each 20 knot increase (210 / 230 / 250 ground speed) we would raise the flap. Note that while the checklist calls for Alternate Flaps for the approach it says nothing about the cleanup. Since Load Relief (which is the problem with normal flaps – the high Airspeed Indication can result in the flaps NOT extending owing to the protective mechanisms of the too smart by half plane) is really only a problem for extending flaps – retraction using the normal system seemed kosher. Still – the option to use Alternate Flap retraction is there.

- Once we got to Flaps Up and the ground speed equivalent to our desired clean speed (230 knots) I would set the book power figure and see if the ground speed settled down at the desired figure.

At about this point, we were a long way from Sydney over the water and approaching the boundary of controlled airspace. We requested a turn back towards downwind – at which point our ground speed increased by about 25 knots. Since we had not adjusted power or configuration – this has to be the change associated from going from a headwind into a tailwind. So we waited to ensure it was stable, decided this new ground speed (238 knots) was the equivalent of our Flap 5 speed (190) and commenced the acceleration/flap retraction manoeuvre. It worked a treat. Flap 5 to Flap Up meant an increase of 40 knots. Once things settled down and the power was set – the ground speed was 278 kts. Lovely.

We were now clean and headed downwind. By the way – somewhere at/before the turn – I handed over to my FO who flew the turn and the acceleration manoeuvre. But before that, having handed over with a brief as to what I was watching (Manual Thrust, Raw Data, monitoring ground speed) – I checked his book figures for the configurations we would need to get the aircraft back on the ground. No errors of course.

Tidying Up

Then (belatedly) I rolled into the rest of the world outside of our little flight deck conundrum. ATC to tell them our state and what our intentions were. Flight Manager to tell him what was going on. PA to the passengers. We got someone to call the Company as well. All the COMM boxes ticked.

As we passed the Airport, and then the initial approach area – we finished off the rest of the Non Normal checklists generated by the event and contemplated our next action – extending Flap and Gear for landing. Of course with a proven method – all we needed to do now was reverse it. What we needed for that was a long, straight run in a constant wind. This turned out to be after we’d flown 40 miles past the airport, reversing course back towards the runway, into wind with another new IAS/Ground Speed relationship.

Configuration for Landing

So having reversed course, we had yet another ground speed to equate to our QRH Clean Speed, and worked out the values of ground speed we would need to see for the Flap/Speed reductions (Flap 1 : -20; Flap 5 : -40; Gear Down, Flap 20 : -60, or actually Vref20+10). We did this in level flight, reducing thrust slightly to allow the aircraft to very slowly bleed off speed as the Alternate Flaps laboured to eventually get the flaps out. There is an FCTM recommendation when using Alternate (or Secondary) Flaps not to reduce speed until the Flaps have reached their next setting. We had previously looked up/cross checked Attitude/Power settings for:

So having reversed course, we had yet another ground speed to equate to our QRH Clean Speed, and worked out the values of ground speed we would need to see for the Flap/Speed reductions (Flap 1 : -20; Flap 5 : -40; Gear Down, Flap 20 : -60, or actually Vref20+10). We did this in level flight, reducing thrust slightly to allow the aircraft to very slowly bleed off speed as the Alternate Flaps laboured to eventually get the flaps out. There is an FCTM recommendation when using Alternate (or Secondary) Flaps not to reduce speed until the Flaps have reached their next setting. We had previously looked up/cross checked Attitude/Power settings for:

Gear Down Flap 20, Level Flight (sort of).

Gear Down Flap 20, Level Flight (sort of).- Gear Down, Flap 20, 3 degree approach

- Go-Around Power (15 degrees IAW with the FCTM, rather than the 18 degrees of the QRH)

- Flap 20, Level at 5000 ft after a missed approach

At which point we discovered that in fact there was no Flap 20, Gear Up Pitch/Power, so we cheated a little and use the Flap 15 value from the QRH, slightly augmented. All of which also went very well.

The Approach and Go-Around all worked out as well. I stopped the pitch attitude just above 15 degrees (rather than the recommended 18.5 degrees) but it didn’t seem to make a lot of difference.

In Summary

In summary – very pleased with how we handled this otherwise challenging non normal. The only sticking point revolves around being pre-prepared for an event like this. But that said – having done it this way once I have a high degree of confidence in needing to handle it on the fly at some point in the future. That’s the benefit of Training!

Ken.

If you find my content useful and are in a position to do so – I would appreciate a contribution to my PayPal account (ken.pascoe@gmail.com) – If you use the Friends and Family feature in PayPal it reduces the charges to the transfer. Please note that when sending money in this way you are removing any form of purchase protection, which is not relevant to a contribution of this type anyway.